Details

Typical components & applications

Typical components

Housings, fuel pumps, pistons, brakes, cooling systems, insulation components, couplings, valve controls, rail car doors, seat parts, suspensions, shock absorbers, ship parts, insulation and cooling units, façades, interior design, lights, window and frame profiles, guide rails, pistons, prostheses, kitchen appliances

Industrial applications

Automotive industry, electrical engineering, construction industry, mechanical engineering, aerospace, aircraft manufacturing, medical technology, household technology, measurement technology, precision engineering

Collini's product portfolio

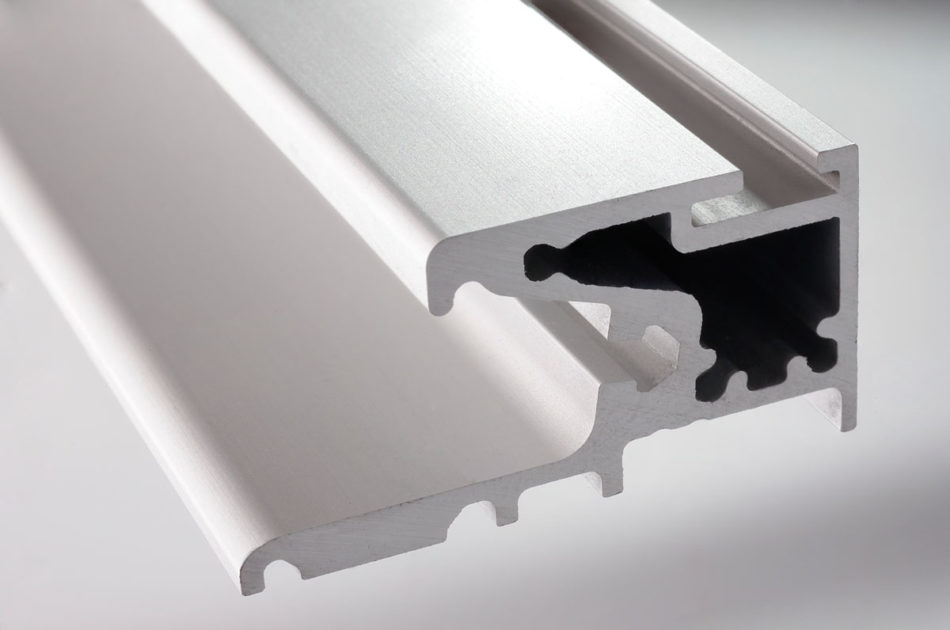

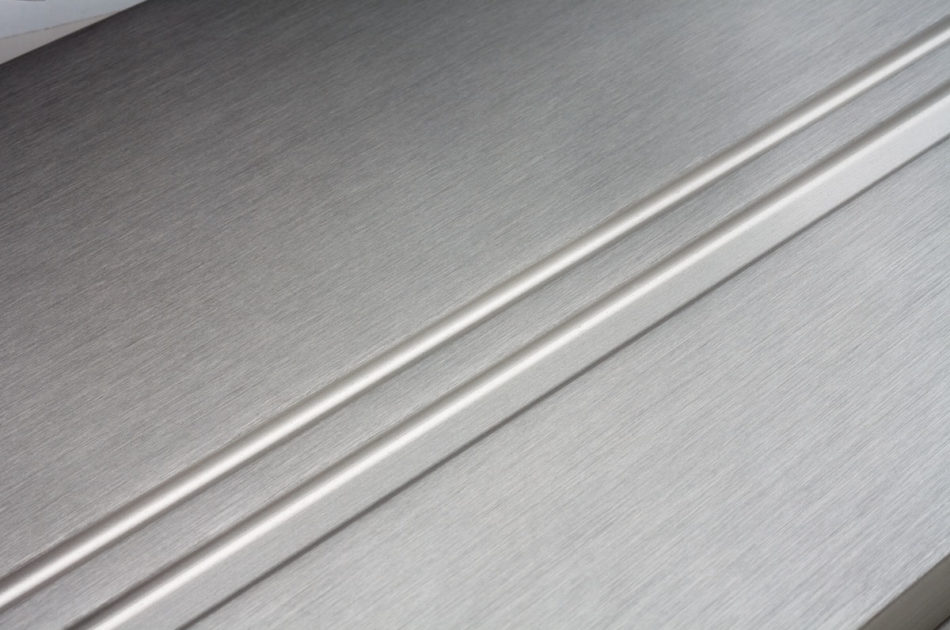

Eloxal

During anodization, the base material aluminium is electrolytically oxidised to produce a 5 to 25 µm thin layer that protects against corrosion. The DC process (DC sulphuric acid) is most commonly used here. The thickness class must be defined for architectural applications. This depends on national standards and the respective aggressiveness of the atmosphere. Basically, there is a distinction made here between interior applications with a minimum layer thickness of 5 µm and exterior applications with at least 15 µm.

Collini has been awarded the QUALANOD quality label and is committed to working in compliance with the strict Qualanod regulations. Holders of this quality label are tested at least twice a year by a neutral entity.

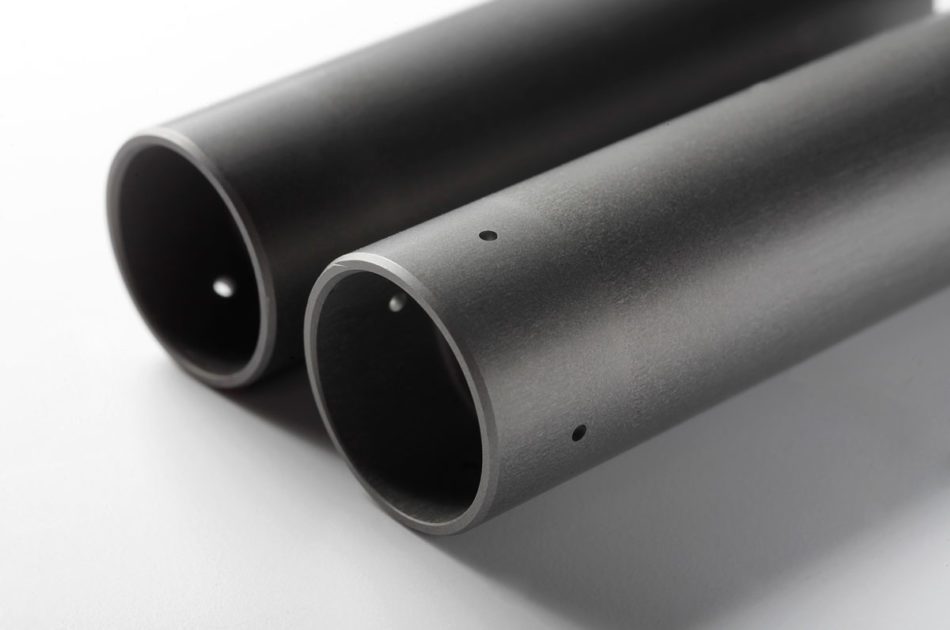

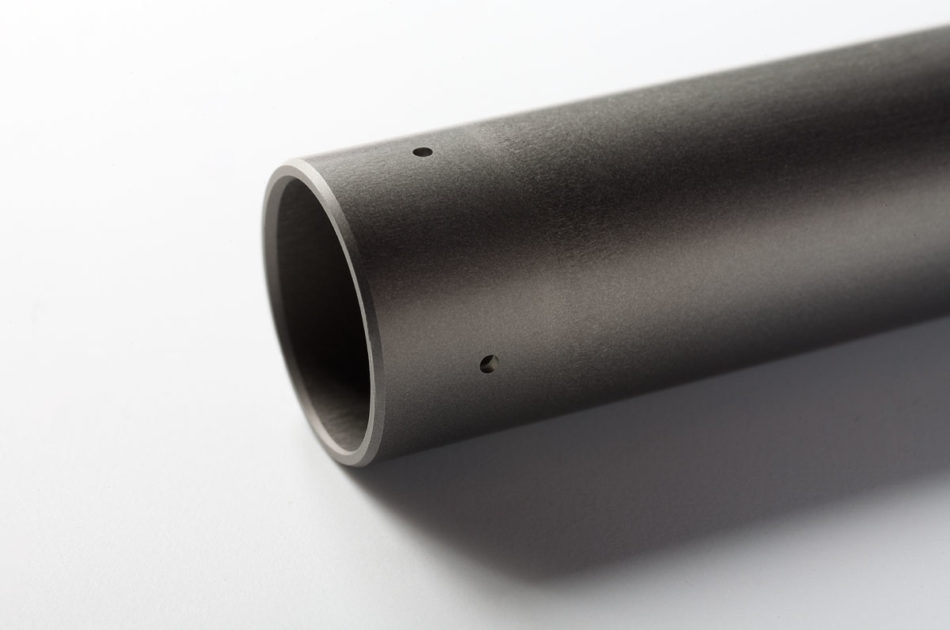

Hard anodising

During hard anodising, the oxide layer develops from the base material and grows 45-50% into it, which ensures good adhesion to the substrate. The layer thickness can be determined by the current density and exposure time. Due to its micro-porous nature, the layer can be dyed by layering with dye material. With appropriate post-treatment, the micro pores can be closed. The anodising layers are hard, corrosion and wear resistant, and they have a good insulating effect. The layer properties can be further modified depending on the anodization method used and the composition of the material. Fields of application include all areas in which aluminium with increased technical specifications is required.

Collini offers Glatox® for special applications where abrasion wear and abrasion corrosion must be prevented. This hard anodised layer with a special structure to achieve an abrasion resistant, smooth surface features low abrasion coefficients, excellent corrosion resistance and a very compact, low-pore layer structure. The coating has been tested in tribological systems and is used in automotive manufacturing systems, amongst others. As an alternative to CrVI-free chromating, Collini has developed the Collossal anti-oxidation coating. This features good corrosion resistance and corresponding conductivity, and also serves as an excellent primer for subsequent coating systems, such as painting.

Titanium anodising

The importance of titanium and titanium alloys is based on two special features. This is a light metal (d=4.5 g/cm3) and, particularly in the alloyed state, a high strength to density ratio can be achieved. Titanium has excellent corrosion resistance. Titanium is used in areas such as aerospace, aircraft manufacturing and as a biometal for surgical fracture treatment. Titanium owes its excellent corrosion resistance to a thin oxide film. This TiO2 layer can be technically adjusted through targeted anodic treatment.

Colour coding: Collini offers titanium anodising in both acidic and alkaline solutions. This means that the thickness of the oxide film can be adjusted from a new nanometres to a few micrometres, which significantly improves the corrosion resistance and the tribological properties of the component. In addition, there is the option for colour coding of titanium components during anodisation in the acidic solution. The Collini Dübendorf location has audited its titanium anodising work area in accordance with ISO 13485.