Details

Typical components & applications

Typical components

Industrial applications

Consumer goods, electrical and industrial engineering, furniture industry, vehicle manufacturing, mechanical engineering, mining, oil and gas industry

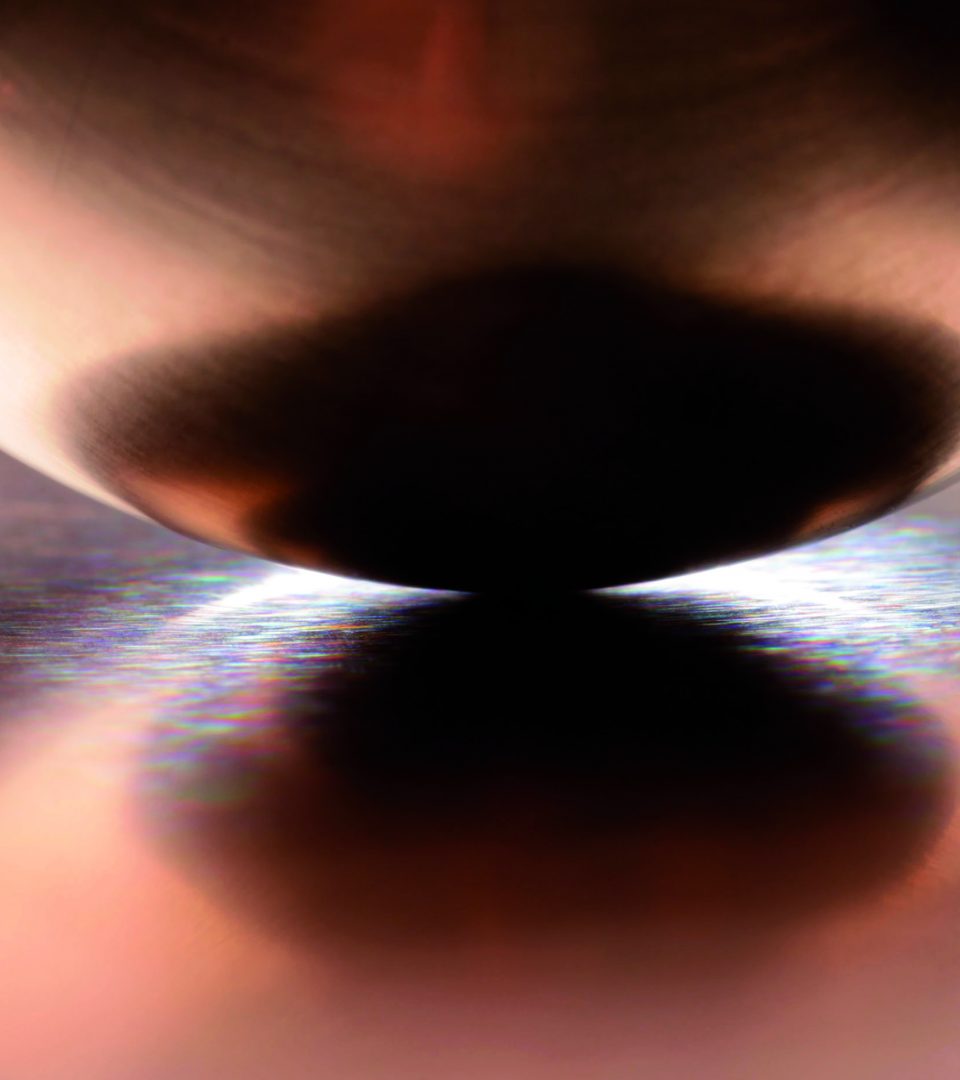

Collini copper surfaces

Collini processes copper in a variety of processes: electrolytically deposited copper up to the highest degree of purity, as well as electricity-free copper coating for the refinement of plastic components. Depending on the process, a semi-gloss to a high-gloss look can be created.