Details

Typical components & applications

Typical components

Industrial applications

Mechanical engineering, commercial vehicles, recreational vehicles and two-wheelers, agriculture, biomass

Collini product portfolio

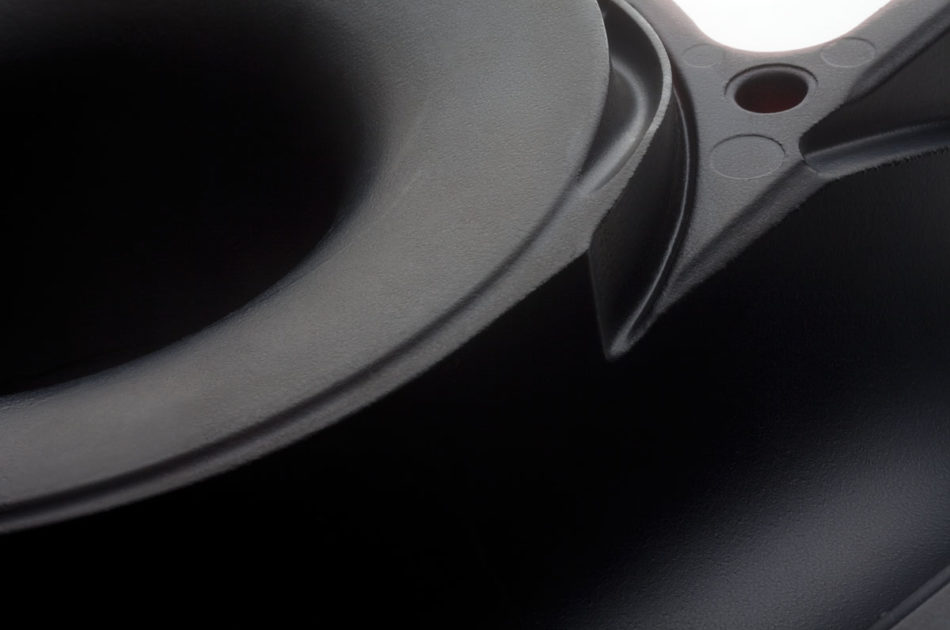

Cathodic dip painting

In CDP, the metal parts are dipped in thin-film lacquer, whereby the lacquer particles are applied evenly by electrostatic charge up to a layer thickness of around 25 µm and then baked at temperatures of approximately 180 °C. CDP is the perfect combination of corrosion protection, quality, economy and environmental friendliness. The coating is fully automatic and even, with no drips or traces of wear. Good edge coverage and coating of undercuts is very easy to achieve because the dip lacquer is very thin and can easily penetrate anywhere.

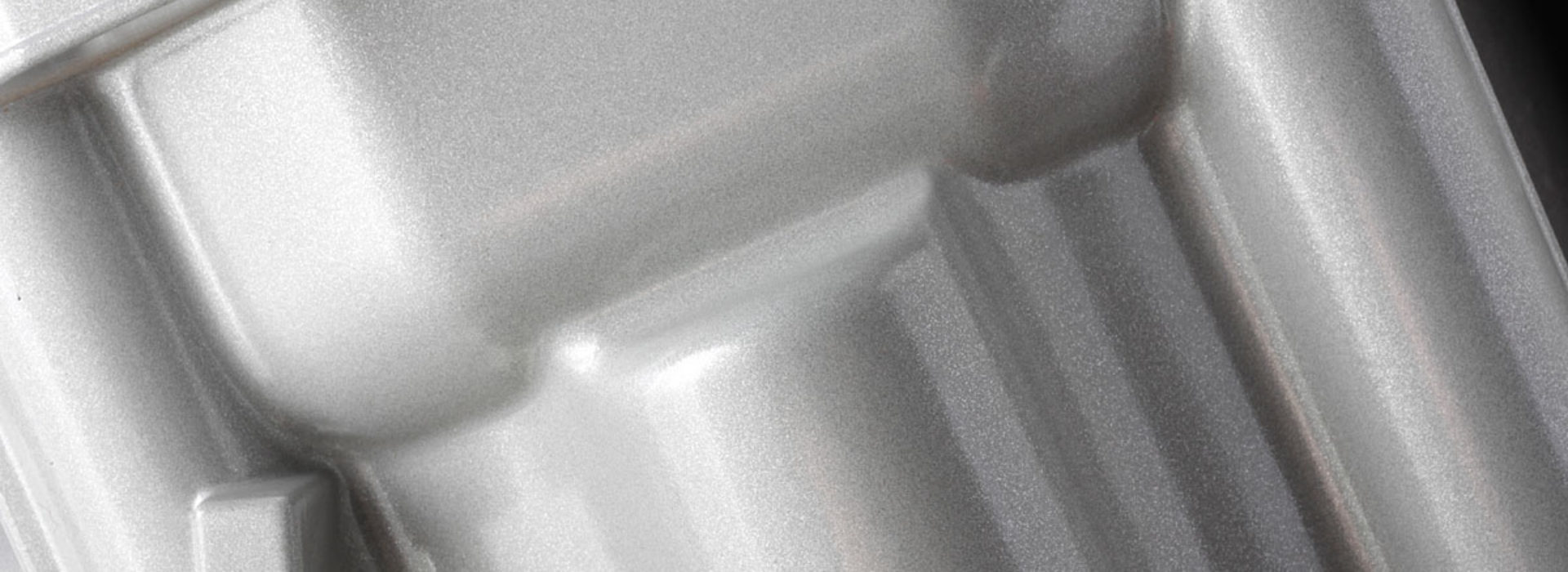

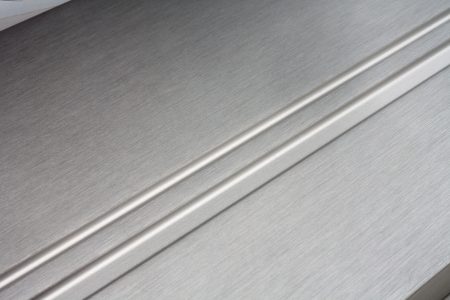

Powder coating

The powder particles, which are electrostatically charged in the powder gun, are blown onto the workpiece during powder coating. The workpiece is grounded so that there is a force of attraction, which makes the colour particles adhere. In the curing oven, they fuse at approx. 200 °C into a homogeneous, resistant powder coating layer (approx. 80 µm thick lacquer layer). The hardening or cross-linking that matches the component results in a perfect coating in terms of mechanical and chemical resistance. By selecting the appropriate type of powder, UV stability can be influenced. The colour hue, surface structures and gloss levels can be freely selected. The gradations from a smooth to a fine to a coarse structure have an influence on the tactile sensation, while the gloss levels, from high gloss to dull matt, complement the desired visual impression. Special effects, such as metallic, hammered or glaze effects complete the extensive range of design options.