Details

Typical components & applications

Hot-dip galvanising has experienced very dynamic development in recent years, but its development potential is far from exhausted. The spectrum of innovations ranges from the introduction of environmentally friendly technologies, through adaptation to high-tech steels and complex components, to the development of new fields of application.

Typical components

Steel structures, façade parts, fences, gates, doors, terraces, balconies, carports, railings, lorry trailers, semi-trailers, transport racks, swap bodies, plant components, power plants, onshore and offshore installations, animal stable equipment, masts, supports, cable car seats and cable car components.

Industrial applications

Steel construction, home and garden architecture, bridge construction, mechanical engineering, agricultural engineering, vehicle manufacturing, plant engineering, cable car manufacturing

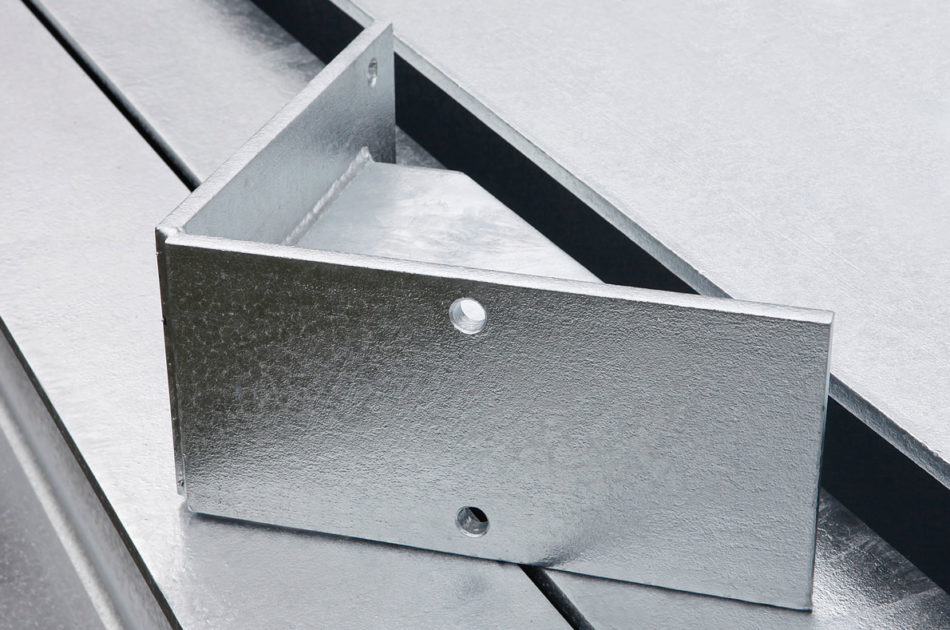

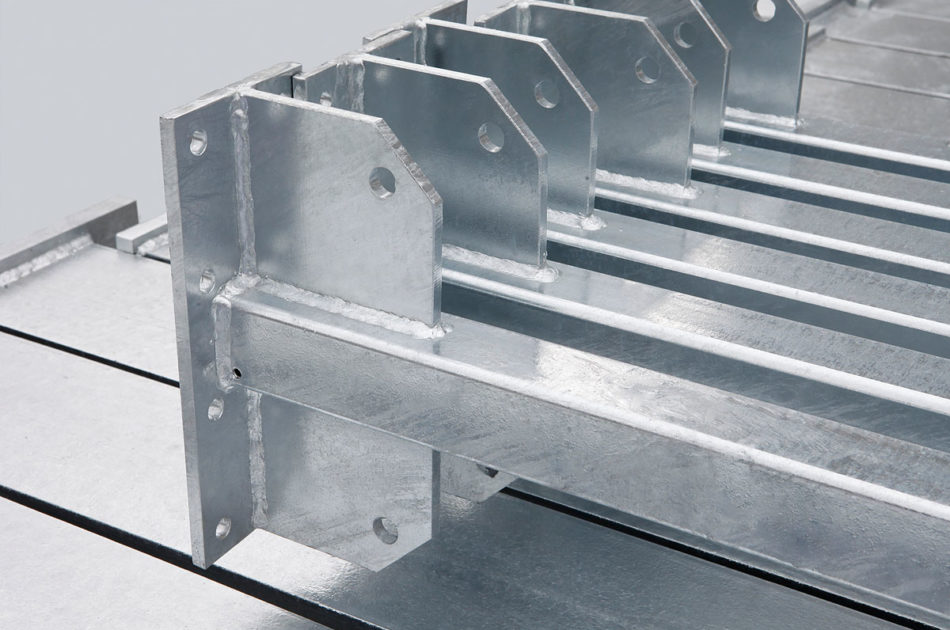

The locksmith's trade represents a traditional application of hot-dip galvanising for individually designed iron and steel structures, such as doors, gates, door frames, railings, fences, balconies and carports that are exposed to the weather.

Hot-dip galvanised structures such as scaffolding, form work, bridges, halls, multi-storey car parks, etc., offer maximum design options and represent an economical solution in the construction industry and its subcontracting areas. Hot-dip galvanising in steel construction makes an important contribution to increasing service life and sustainability.

The vehicle manufacturing and agricultural sectors offer their customers designs, equipment, machinery and vehicles for tough conditions. Dirt, deposits, stone chips, snow, rain, de-icing salts and animal excrement place high demands on corrosion protection in everyday life. It must be resistant, durable, abrasion resistant and offer the best cost-performance ratio. Hot-dip galvanised steel has proven to be excellent for use in these areas.

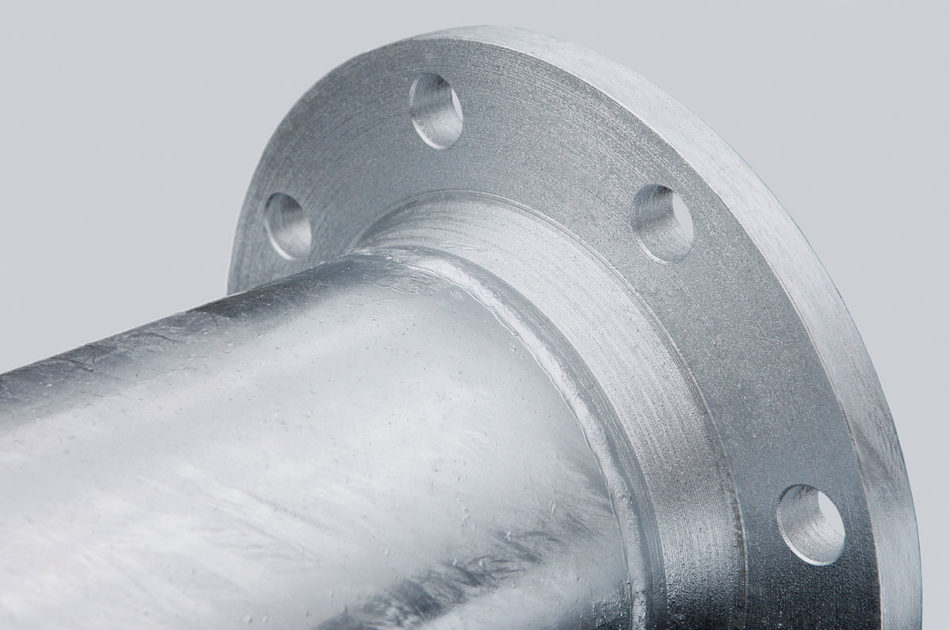

In plant construction, all exposed components receive perfect all-round protection with hot-dip galvanising, even in hard-to-reach places, as well as long-term protection without maintenance for many decades. There is a wide variety in terms of areas of application, which range from mechanical engineering and plant construction to cable way construction.

Collini surfaces

Hot-dip galvanising of piece goods in the dipping process

The inseparable bond between zinc and steel is unique in the hot-dip galvanising process. The steel is not simply coated with zinc (as with painting or coating). It actually undergoes a metallurgical reaction, which is the alloy formation. A pure zinc layer (Zn Eta) Zn 100% Fe 0% settles on the surface, over the alloy layers (Fe-Zn Gamma) Zn 75% Fe 15%, (Fe-Zn Delta) Zn 90% Fe 10%, (Fe-Zn Zeta) Zn 94% Fe 6% and when moving out of the molten zinc. As a result, the corrosion protection of hot-dip galvanised parts is extremely high, and the layer is extremely generally resistant and abrasion resistant.