Details

Typical components & applications

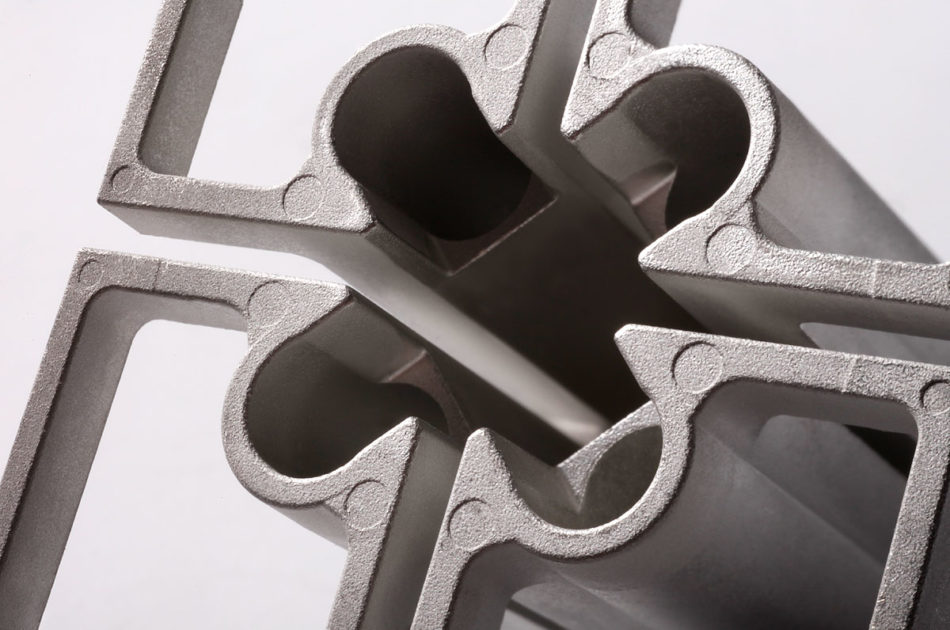

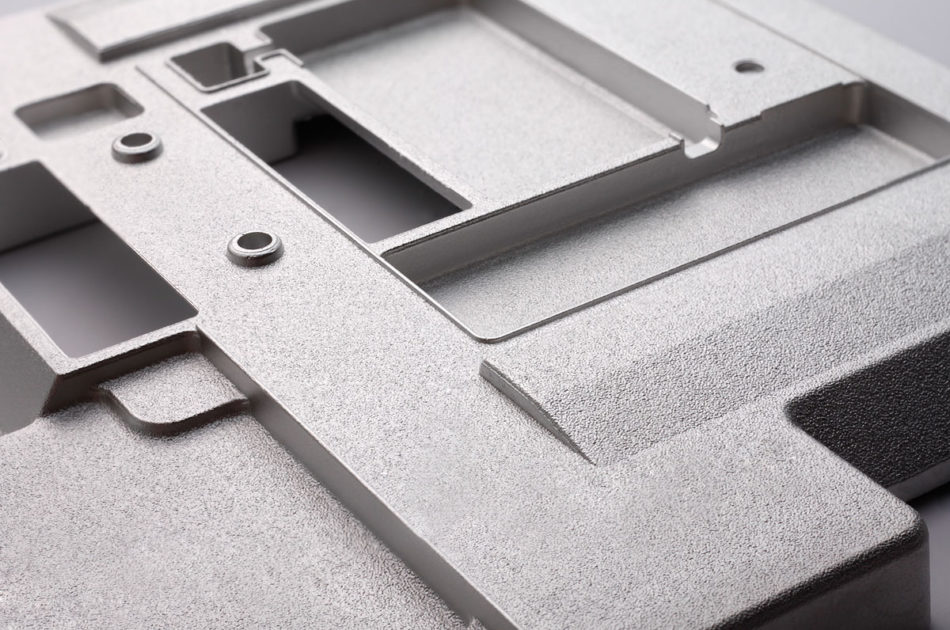

Typical components

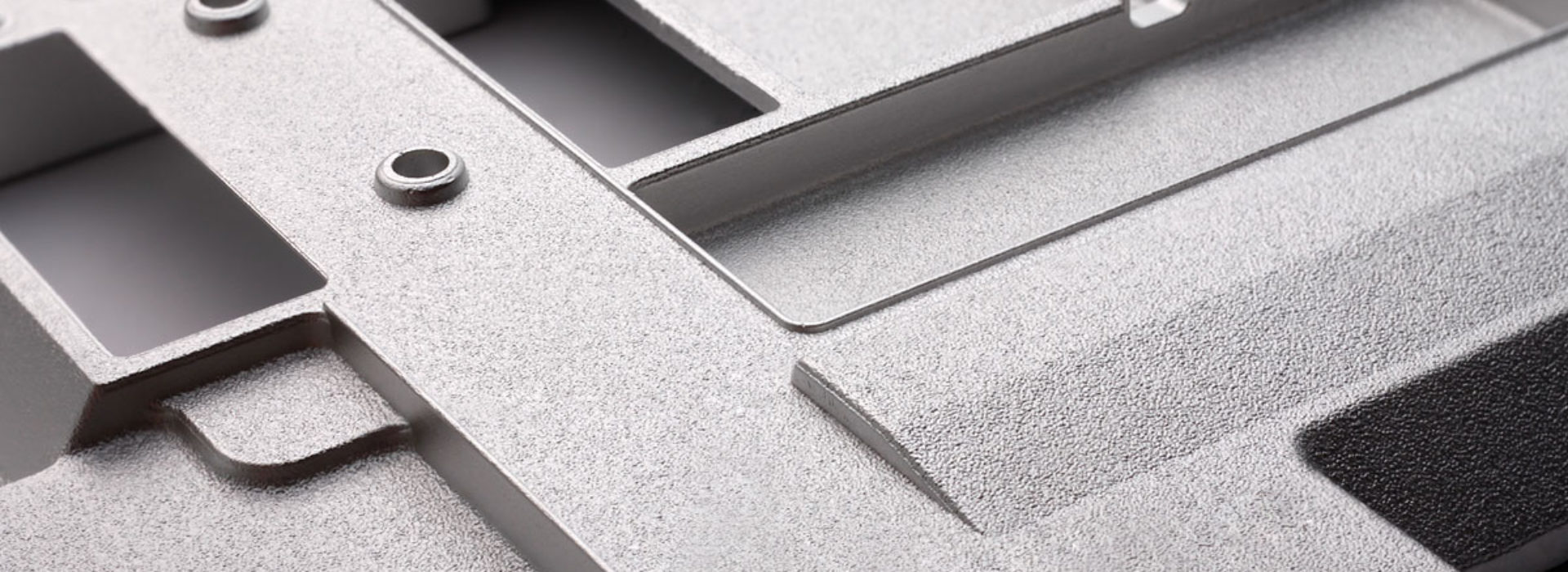

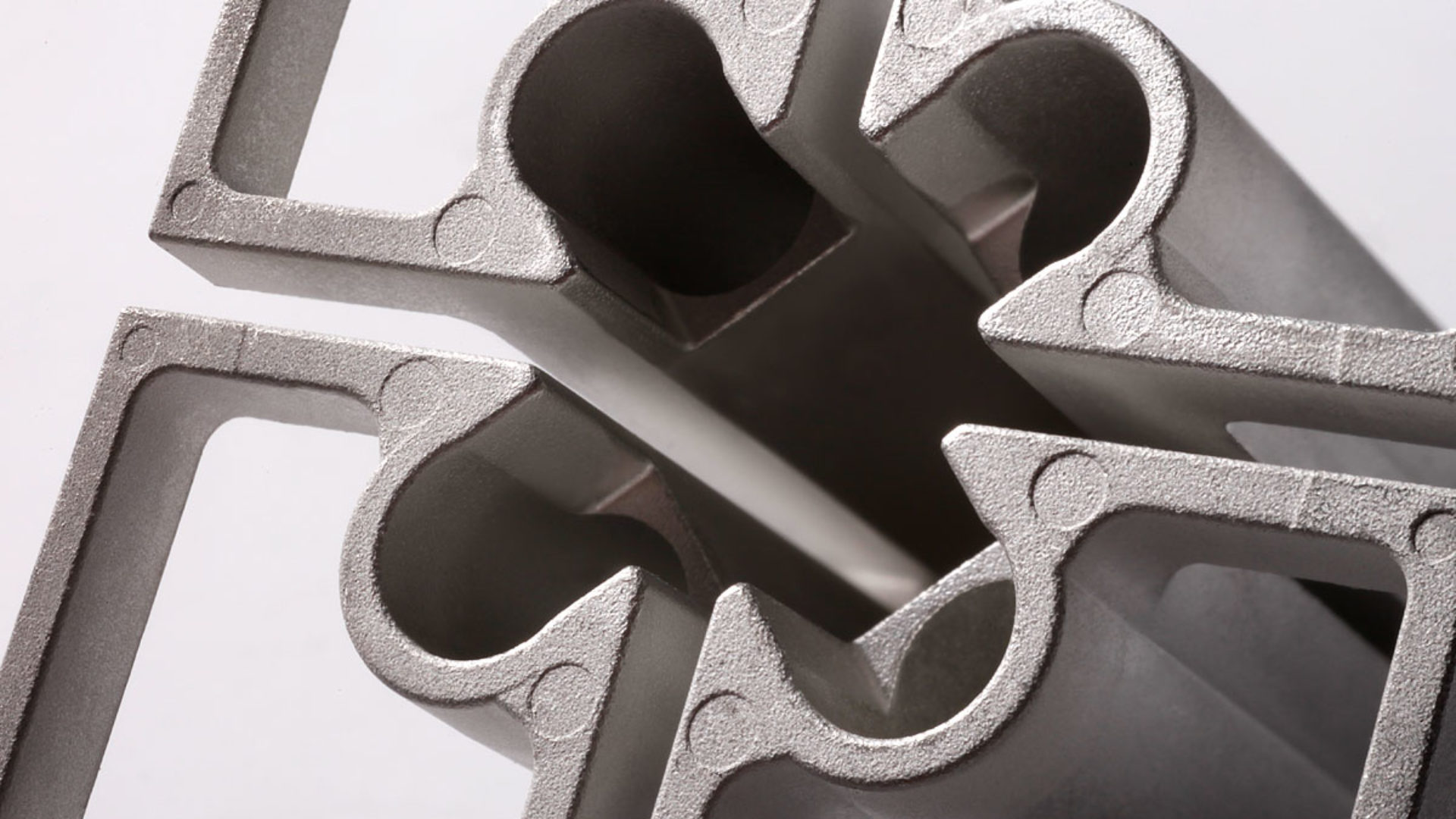

Connectors, contacts, electrical housing units, battery terminals, automotive electrical connections, kitchen appliances, furniture fittings, cooling plates

Industrial applications

Electrical engineering, electronics, automotive industry, mechanical engineering, furniture industry, food industry

Tin surfaces in the portfolio

Galvanic tin process

In tin plating, a silver-white surface is produced in an electrolytic tin bath, which is covered with a thin layer of oxide in air. The base material is primarily steel, non-ferrous metals and aluminium with an intermediate layer. In addition to its decorative appearance, the tin surface has multiple functional properties, such as corrosion protection, chemical resistance, high ductility and good layer thickness distribution.

Lead-free tin

Our tin process is lead-free and therefore complies with Directive 2002/95/EC(RoHS) of the Electrotechnical and Electronic Industry, as well as the End-of Life Vehicles Directive.

Combination coatings

In combination with other layers - SkinTech® - the functional properties of tin layers can be further modified.