Details

Typical components & applications

Typical components

Trim parts, control components, fittings, mountings, home electronics, brake and clutch components, fuel pumps, pump housing units, turbo-compressors, gear parts, suspension systems, rivets and sheet metal parts that are crimped; closing and lock systems, ball valves, energy supply technology, mountings, pipes, tool components

Industrial applications

Automotive, automotive engineering, plumbing, construction, furniture, electronics, electrical engineering, wind power, safety technology

Nickel surfaces in the portfolio

Glossy nickel

Glossy nickel (mirror gloss) is preferred for highly decorative surfaces and is used as an intermediate layer for glossy chrome plating, which can be changed back to matt with intermediate polishing. Layers are used very often in the sanitary industry. At 650 HV, nickel layers are relatively hard and tough.

Sulfamate nickel

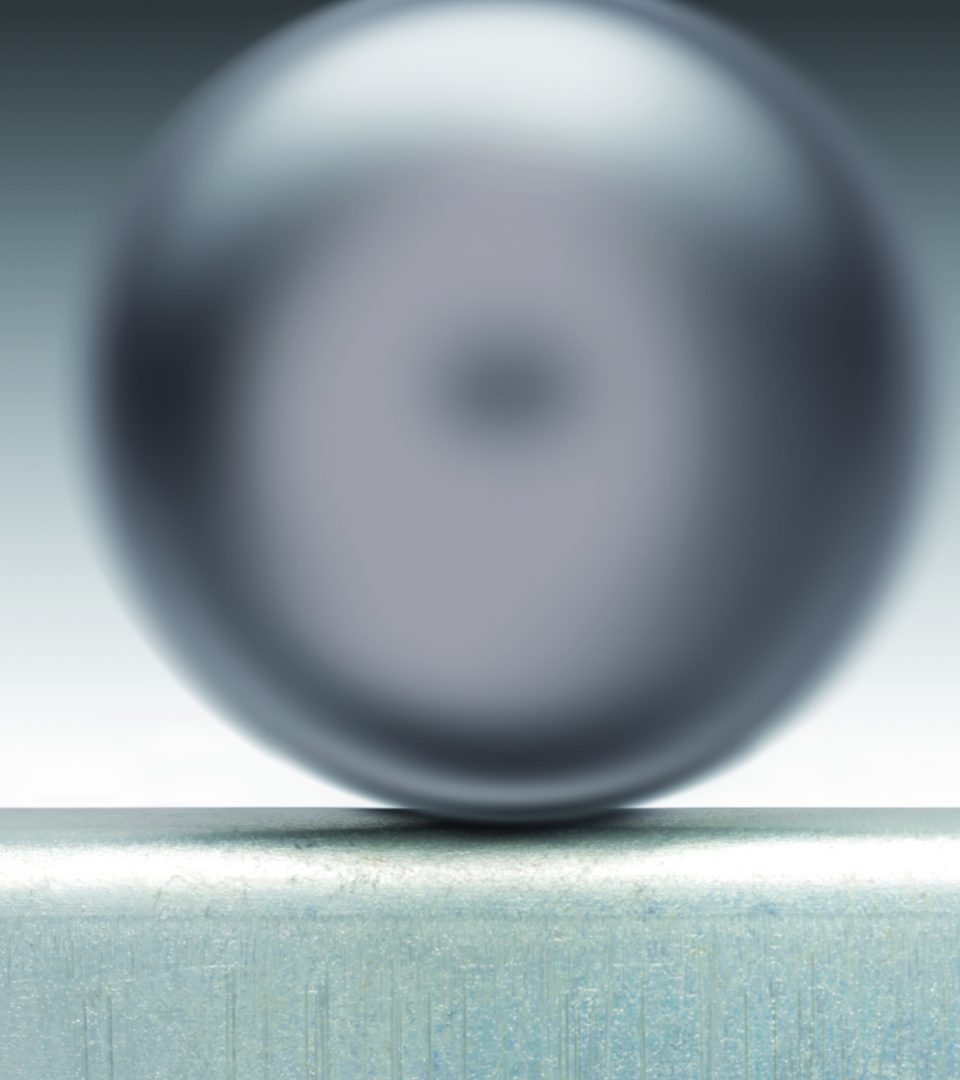

Sulfamate nickel is a purely technical nickel process in which very ductile nickel layers are deposited (due to the low internal stresses), which can be easily reshaped. Typical applications are rivets and sheet metal parts that are then crimped.

Matt nickel

Matt nickel (low to medium level of gloss) is characterised by relatively good ductility. Non-glossy layers are deposited for decorative reasons. Pearl nickel (even matt nickel surface) is suitable for decorative purposes. The low-glare nickel surface is achieved by depositing very fine organic droplets. The layer can then be chrome plated. The primary application areas are decorative parts, control components and fittings for the automotive industry, windows and doors, mountings, home electronics and the furniture industry, all in the purely decorative area.

Black nickel

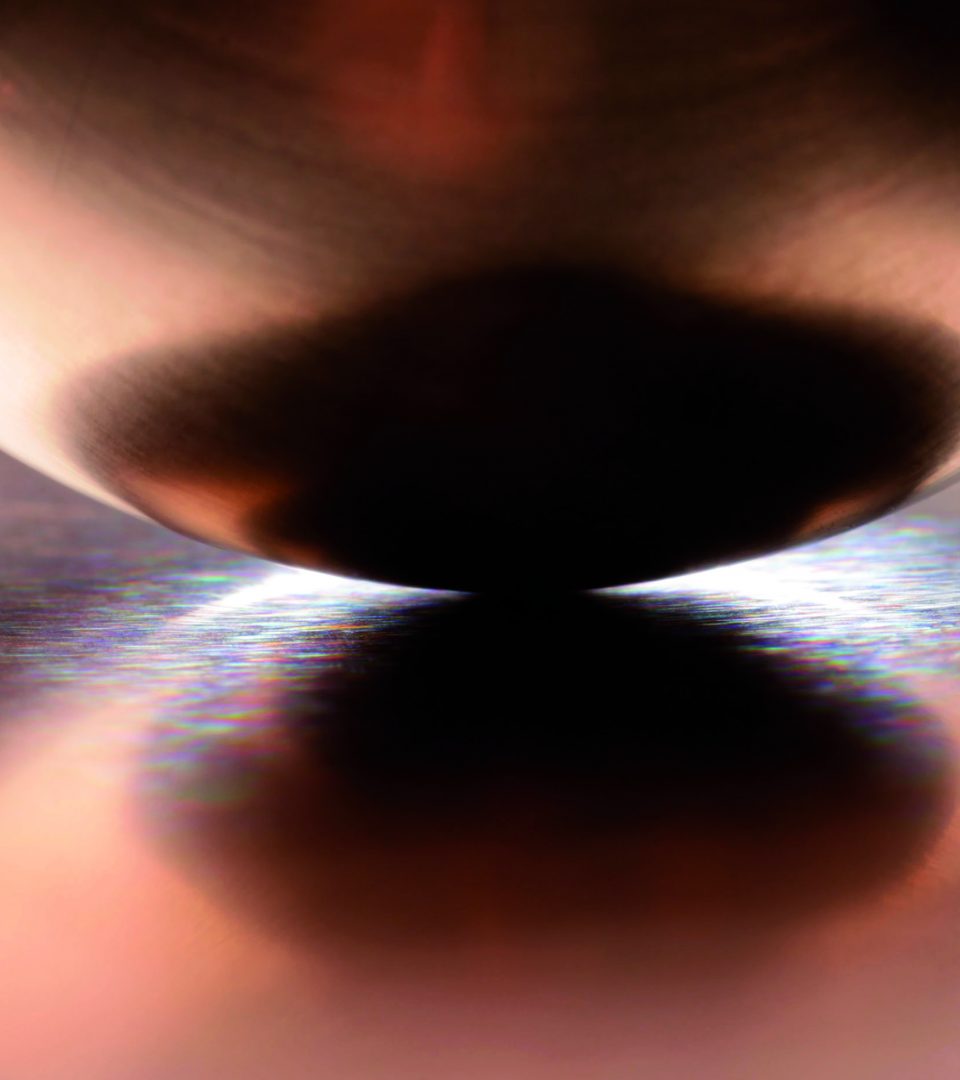

Black nickel layers feature a decorative anthracite colour. They are usually deposited on a glossy nickel layer because the black nickel coatings, due to their brittleness, are only deposited with the highest level of 2 µm. These surfaces are used for coating furniture fittings, as one example.

Chemical nickel

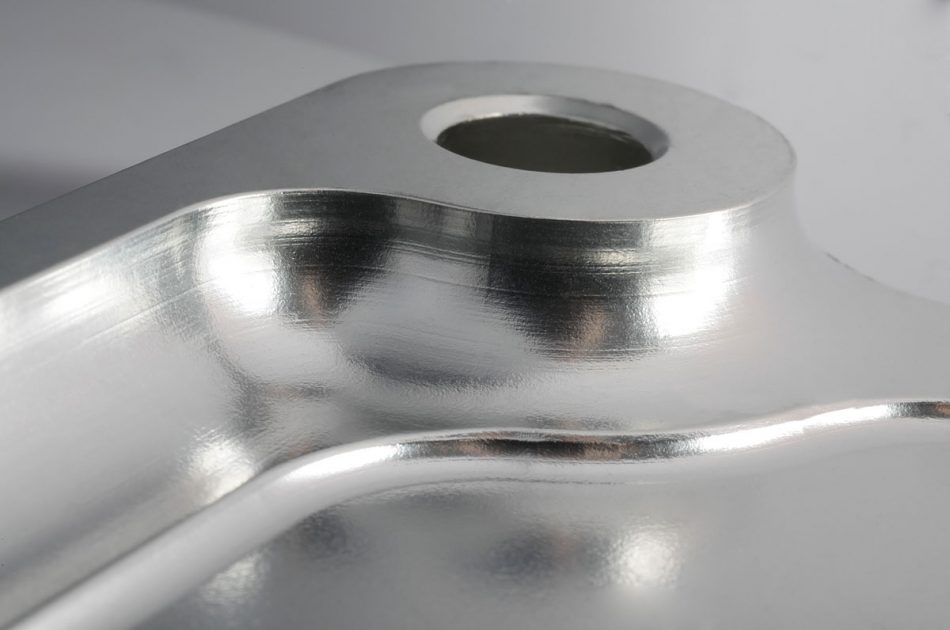

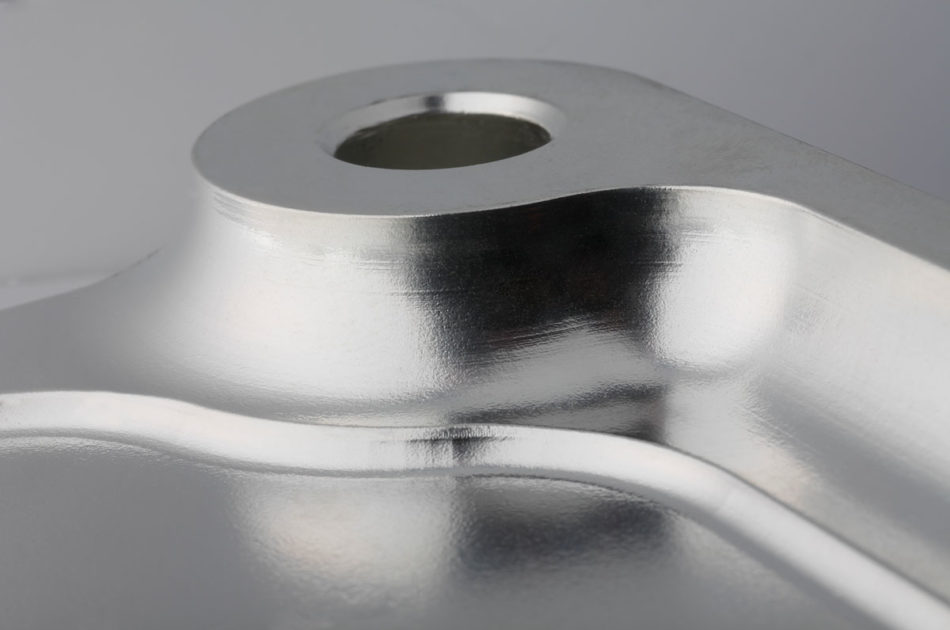

The decisive advantage of chemical nickel is the completely uniform layer thickness distribution with low layer thickness tolerances, which makes it possible to coat even complexly shaped components with cavities or holes, covering every contour. The properties of chemically produced nickel layers can be controlled based on products, depending on the alloy proportions. They can also be combined with one another in one system, which results in a wide range of applications in almost all industrial sectors.

Homogeneous incorporation of nano scale, slippery PTFE particles into a chemical-nickel layer as a stable matrix produces a dispersion layer - Triflon® - that has excellent tribological properties. The high wear resistance and the good sliding properties are paired with extremely low adhesion to water, oil and dirt. Optimal dry run behaviour is also ensured.

SkinTech®, a composite coating with chemically deposited nickel-phosphorous as a hard base layer and galvanic cover layers, which comply with the respective load profile, offers a variety of design options. Tribological requirements, such as abrasion wear, fretting (vibration corrosion), a stable low coefficient of abrasion, extremely high corrosion protection, and decorative and electrical properties can be adapted to specific requirement profiles.