Details

Typical components & applications

Typical components

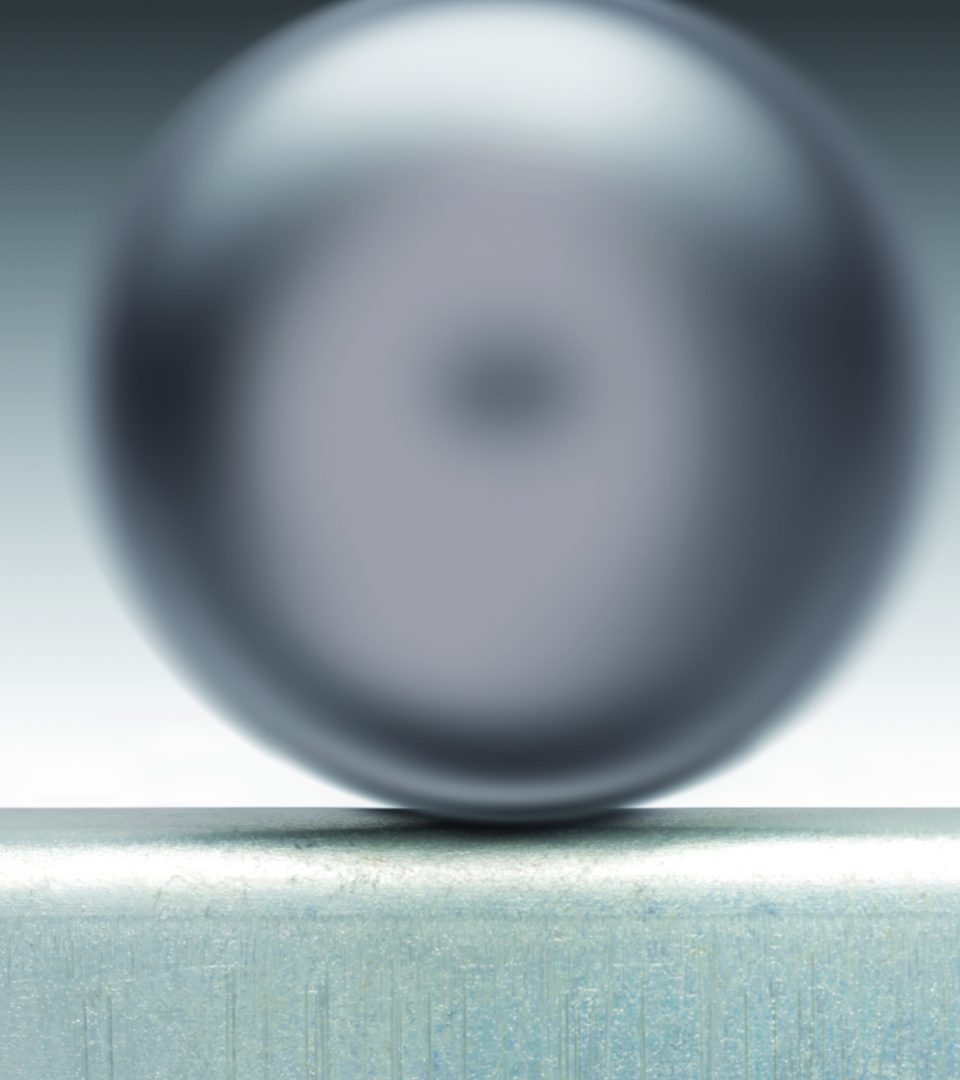

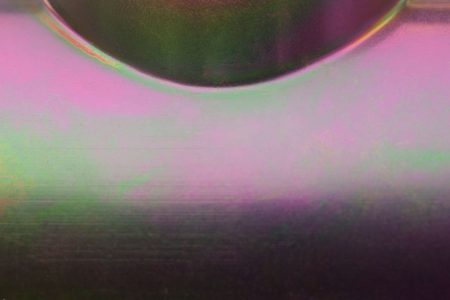

Contact applications with low contact resistance, contact housing applications with decorative requirements, switching contact applications with high wear resistance, sliding contact applications with low contact resistance, plug contacts, bonding surfaces, reed contacts, slip rings, electrical contacts, connectors, micro-relays, RF components

Industrial applications

Electrical engineering, medical technology, wind power, crane technology, vehicle manufacturing, industrial robots, mechanical engineering

Precious metal surfaces at Collini

For precious metal coatings, Collini offers all the common precious metal surfaces, such as silver, gold, palladium, rhodium and ruthenium. Our speciality is gold and silver coatings.

Pure gold & hard gold

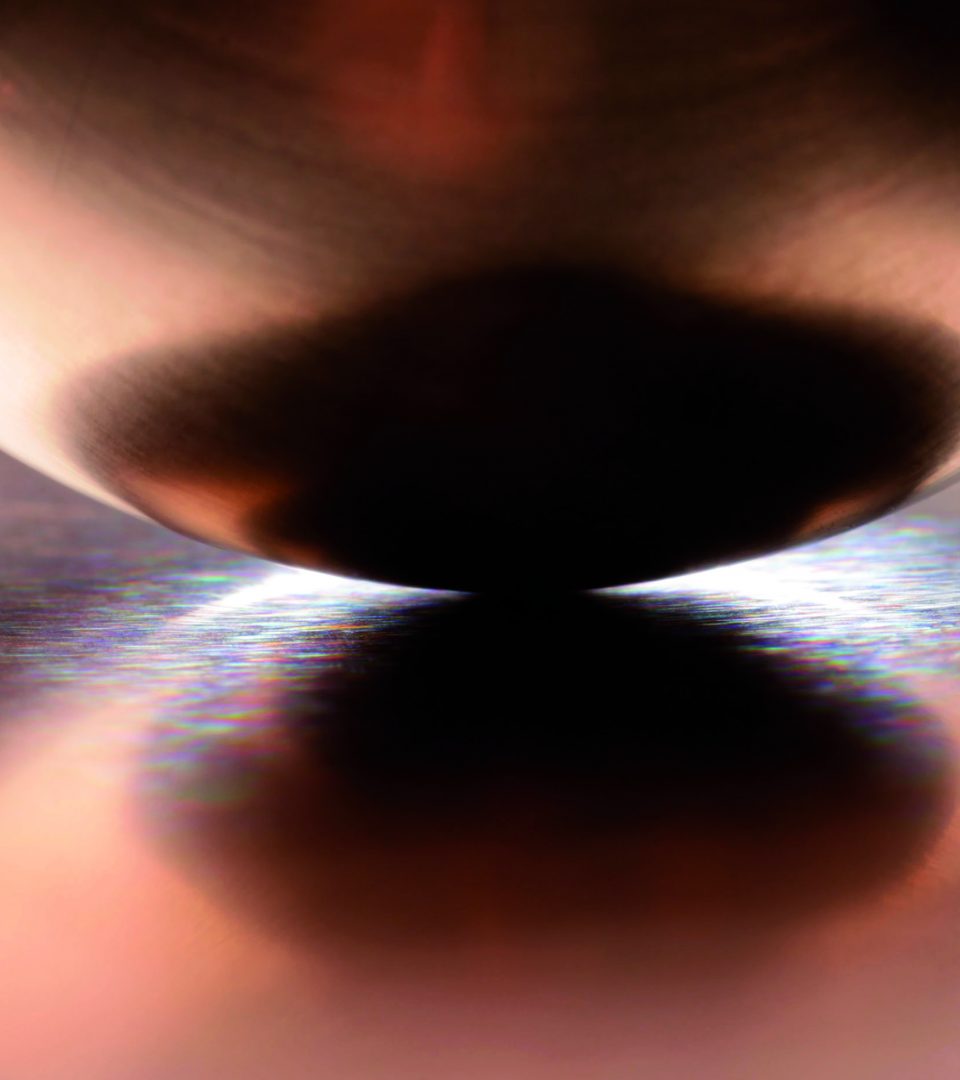

Collini offers a wide variety of gold surfaces. Pure gold (> 99.99% Au) with the highest ductility and elasticity for special applications. Hard gold (> 99.8% Au) with the alloy element of cobalt as the proprietary DUOR® process for multiple applications in the area of connectors and plugs. In the innovative Tribor® system, as an alternative to conventional Ni-Au surfaces, Duor® is deposited in a coating thickness of only 0.15 µm as contact gold on a corrosion and wear-resistant nickel alloy (Niphoplate®). Hard gold (approx. 75% Au) with the alloy elements of copper and cadmium as the proprietary Galvatronic® process, with its extraordinary properties in terms of wear resistance. Due to its possible elongation of up to 5%, this single-phase ternary gold allow can be deposited in coating thicknesses that are far higher than in conventional binary hard gold alloys) (AuCo, AuNi). These properties make Galvatronic® the ideal surface for sliding contact systems such as a slip ring for the wind power industry, for example, where relatively thick hard gold layers result in a long product life.

Pure silver & glossy silver

For silver surfaces, Collini offers high purity pure silver and glossy silver surfaces (< 99.99%). To prevent oxidation, Collini uses RoHS-compliant passivation systems. Optargen®, an in-house developed coating system, protects surfaces from environmental influences over the long term without impairing the functional properties of the surfaces. The base layer is also coated with an extremely thin nickel-free metallic allow layer. High-purity silver coatings can be coloured deep black at Collini in a downstream chemical process. This highly light-absorbing surface is used in the aerospace industry, amongst others.