Employees from 37 countries contribute to Collini's success.

Together with our customers, we have been developing individual surface solutions for 125 years, making their products more successful.

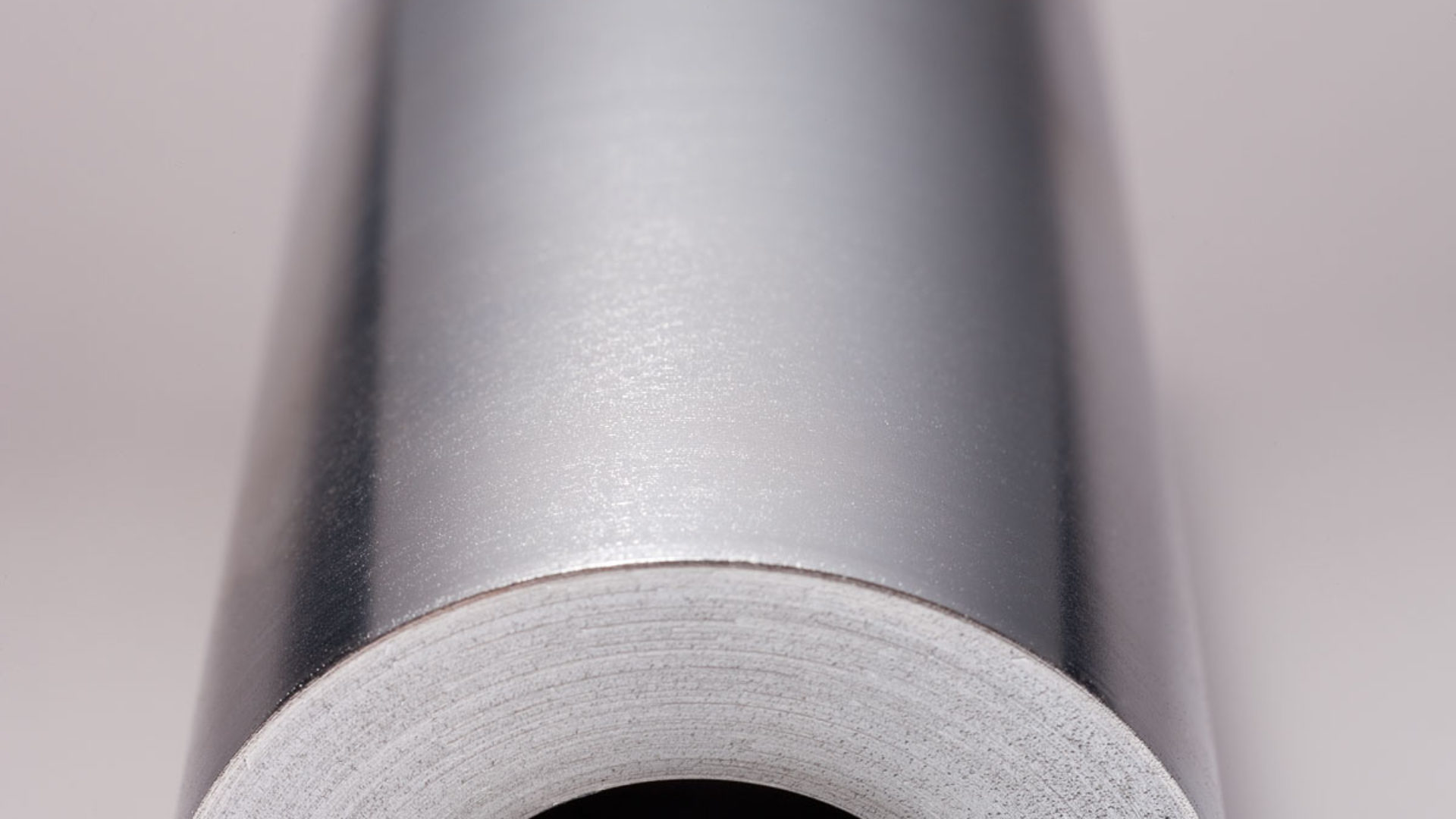

In contrast to the conventional galvanising process, no foreign metallic cover layer is applied during anodising. Instead, the surface of a light metal component is converted into an oxide layer by the galvanising/anodising process.

read more

With gold, silver, palladium, ruthenium, rhodium and platinum, finishes are created in the truest sense of the word. In addition to pure metal layers, precious metal alloys are also deposited through galvanisation.

read more

Hot-dip zinc is used to guarantee extremely stable corrosion resistance wherever a robust, durable surface is required.

read more

Galvanic zinc coatings are used for cathodic corrosion protection of steel and zinc die-cast components. The zinc coating dissolves first, thereby protecting the component against corrosive attacks.

read more

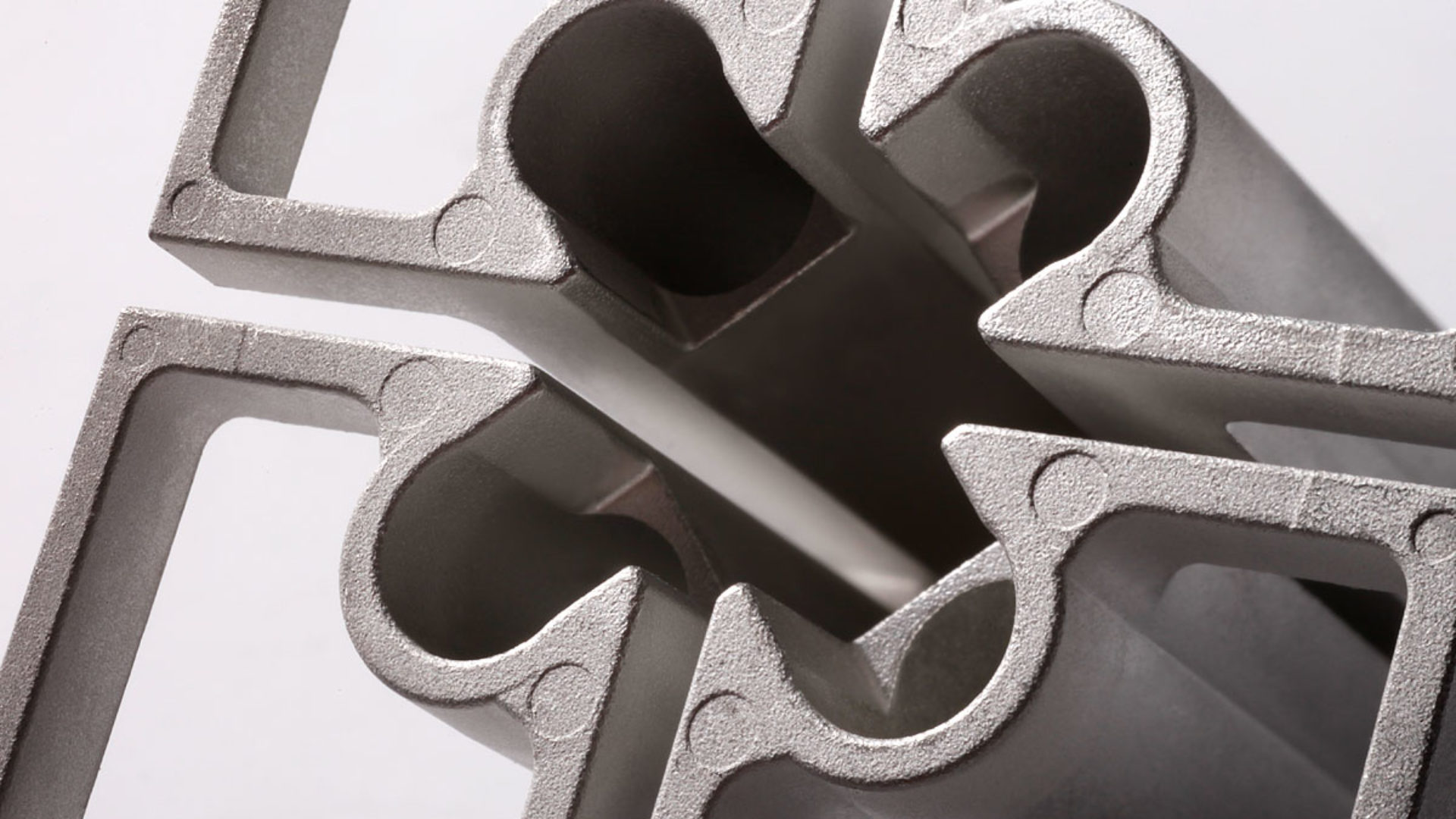

Painting technology is one of the most widespread and traditional surface treatments in industry. The design options in terms of colour, structure and gloss are limitless, while also providing optimal corrosion protection.

read more

Chrome plating is a proven, extremely versatile coating process that stands out because of its extensive list of positive properties. It is highly decorative, corrosion resistant, hydrophobic, and abrasion and wear resistant.

read more

Nickel is the all-rounder of surface technology. With its diverse properties, nickel is one of the most important and frequently used coatings. Collini offers galvanic and chemical nickel surfaces.

read more

Galvanised copper coating combines protection, functionality and aesthetics. Copper is an excellent conductor of electricity and heat, and is often used as the first building block for many coating systems.

read more

Tin is characterised by significant electrical potential. It is extremely conductive, solderable, self-lubricating and compatible with foods. The tin surface also has multiple functional properties, such as corrosion protection, chemical resistance, and high ductility.

read moreIn contrast to the conventional galvanising process, no foreign metallic cover layer is applied during anodising. Instead, the surface of a light metal component is converted into an oxide layer by the galvanising/anodising process.

read moreWith gold, silver, palladium, ruthenium, rhodium and platinum, finishes are created in the truest sense of the word. In addition to pure metal layers, precious metal alloys are also deposited through galvanisation.

read moreHot-dip zinc is used to guarantee extremely stable corrosion resistance wherever a robust, durable surface is required.

read moreGalvanic zinc coatings are used for cathodic corrosion protection of steel and zinc die-cast components. The zinc coating dissolves first, thereby protecting the component against corrosive attacks.

read morePainting technology is one of the most widespread and traditional surface treatments in industry. The design options in terms of colour, structure and gloss are limitless, while also providing optimal corrosion protection.

read moreChrome plating is a proven, extremely versatile coating process that stands out because of its extensive list of positive properties. It is highly decorative, corrosion resistant, hydrophobic, and abrasion and wear resistant.

read moreNickel is the all-rounder of surface technology. With its diverse properties, nickel is one of the most important and frequently used coatings. Collini offers galvanic and chemical nickel surfaces.

read moreGalvanised copper coating combines protection, functionality and aesthetics. Copper is an excellent conductor of electricity and heat, and is often used as the first building block for many coating systems.

read moreTin is characterised by significant electrical potential. It is extremely conductive, solderable, self-lubricating and compatible with foods. The tin surface also has multiple functional properties, such as corrosion protection, chemical resistance, and high ductility.

read morelocations worldwide

million euros in annual sales in 2023

employees worldwide